Reviewed by:Jos van den Nouwland – Product Manager for CG Drives & Automation

Don’t let a VFD fault stop your operations

We at Emotron know that it can be frustrating when you have to troubleshoot a Variable frequency drive and the faults that can occur. Taking care of an HVAC system, working with industrial automation, or being in production can be challenging. Knowing how to quickly fix a VFD drive can help. It can save you time, money, and stress.

This guide shows you a simple seven-step process. It is made for both technicians and operators. You will learn how to find and fix common VFD problems quickly. We can provide you with dedicated Emotron Product Training. This will help you fix problems with your VFD!

Check Chapter 12 Troubleshooting, Diagnoses and Maintenance in our Emotron Instruction Manual

Step 1. Check the Display Panel for Fault Text

When a VFD trips, it almost always shows a fault code or clear text on the display. These codes and texts tell you what type of issue has occurred—electrical, thermal, mechanical, or control-related.

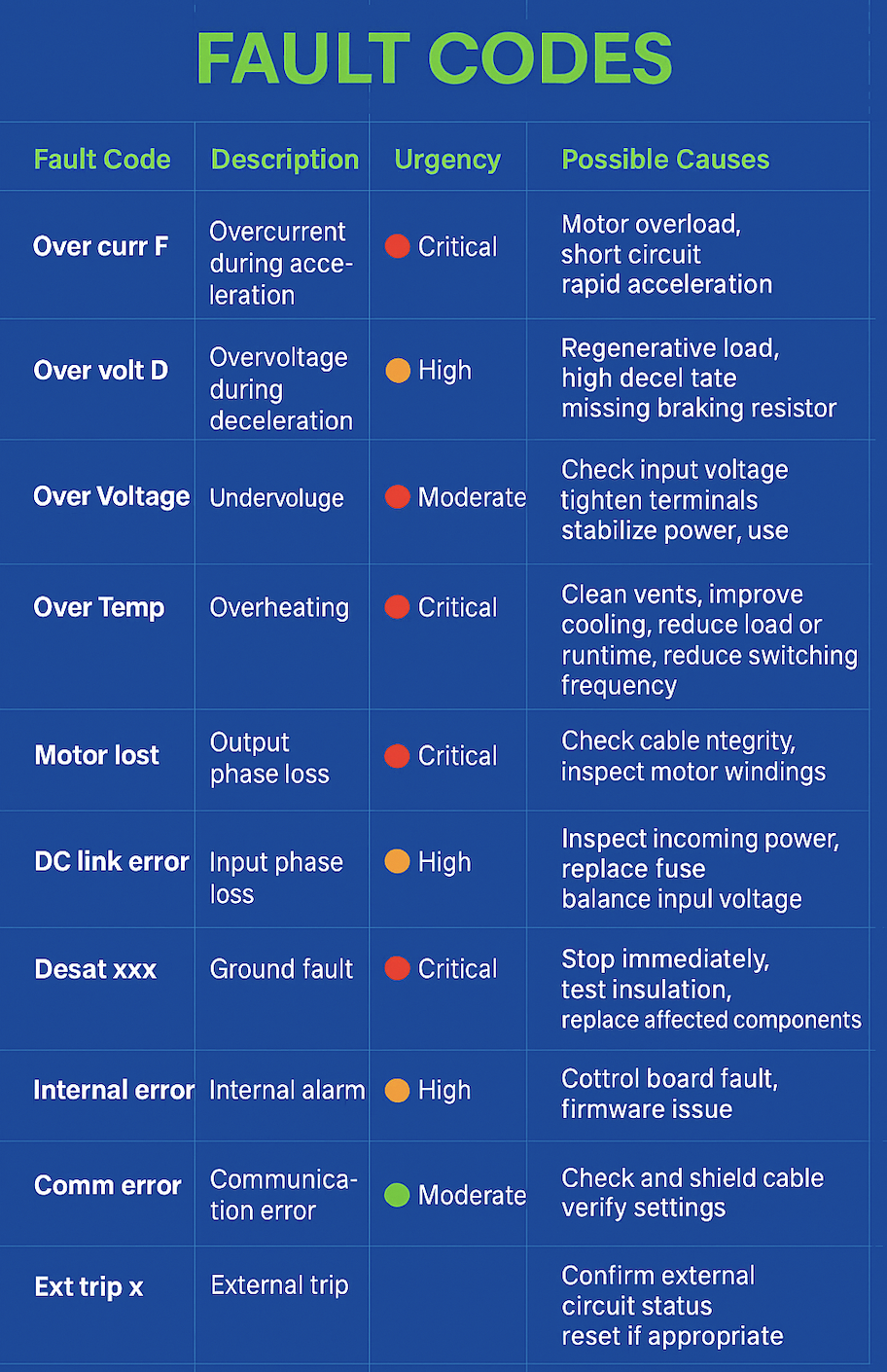

If you are using an Emotron VFD, like the VS10/30, DSV15/35, FDU or VFX series, check the table below. It will help you find the problem and see how urgent it is to fix.

How do you troubleshoot a VFD from Emotron?

There are different methods to use, depending on the error message you encounter. Below in this table, you can see the most common problems and how to fix them.

First look at the Emotron fault code table with urgency levels

Urgency Key:

🔴 Critical = Immediate risk to safety or equipment

🟠 High = Action needed soon to avoid failure

🟡 Moderate = Monitor closely, fix soon

🟢 Informational = Not dangerous, but check system

Once you’ve identified the fault and its urgency, you’re ready to move to the next step: isolating and correcting the root cause.

Best fit for:

Cranes, hoists, robotics, mills, test benches and machinery that experience frequent or abrupt torque changes.

Step 2. Inspect power supply and connections

Many VFD issues stem from loose terminals, voltage drops, or unstable input power. Check:

- All wiring and terminals are tightly secured

- Input voltage is stable and within rated limits

- Signs of overheating or burn marks at contact points

Subscribe to our industrial control newsletter

Step 3. Find the root cause—not just the symptom

Don’t just clear the fault and restart. Understand why the issue occurred:

- Overcurrent might result from a blocked load or too heavy load

- Overvoltage could be from regenerative braking without proper resistors

- Phase loss might indicate a failed fuse or loose connection

Step 4. Evaluate environmental conditions

Different types of VFD:s are sensitive to their surroundings. Dust, heat, and poor airflow commonly cause faults like Over Temp (Overheat).

Checklist:

- Is ventilation adequate?

- Are filters and fans clean?

- Is ambient temperature within operating limits?

Step 5. Inspect the motor and load

A motor problem often shows up as a VFD fault. Check:

- Motor condition using an insulation tester

- Mechanical binding or load imbalance

- Proper cable sizing and condition

Technician toolbox – Common tools when troubleshooting

- Megohmmeter (Insulation Tester – testing with high voltage): Detects ground faults or moisture in motor windings (useful for faults like Desat xx).

- LCR Meter or Cable clamp-on Current Meter is suitable for use in combination with VSD’s: Supports diagnosis of Over Curr (Overcurrent), Motor Lost (Output Phase Loss), and Desat (Ground Fault/short circuit).

If the windings are not balanced, a motor may use too much or uneven current. This can lead to overcurrent faults, heating problems, or activate output protection.

- DMM Multimeter: Used for nearly all fault diagnostics

Emotron faults like: F003 – Undervoltage, F006 – Input Phase Loss and F009 – Communication Error (if using 24V controls).

All require confirmation of:

- Voltage on input terminals.

- Output voltage during operation. (Check allowed isolation of devices and suitable for measuring VSD’s output voltage).

- Control signal continuity.

Thermal Camera (optional): Useful for spotting hot spots or overload conditions in control panels. Especially good for diagnosing Over Temp – Overheating, Motor PTC – Motor Overheating and Over Curr – Overcurrent.

- Hot spots on the VFD enclosure may signal blocked ventilation or failed cooling fans.

- Overloaded motors or cables show uneven heating patterns.

- Can help validate environmental causes of VFD trips.

Step 6. Reset the VFD and monitor performance

After correcting teh issue, reset the drive via:

- Reset button

- Power cycle (if safe)

- External signal input

Closely monitor the motor after restart—look for recurring faults or strange behavior.

Tip: Always reduce the load during the first restart cycle after troubleshooting.

Step 7. Log the issue and plan for prevention

Once resolved, document the event and take steps to prevent recurrence.

Include:

- Fault type and code

- Cause and fix

- Operator observations

When to call a specialist

Some faults go beyond general troubleshooting:

- Internal or repeated control board or DESAT faults (Internal error or PF xxx err)

- Burning smell or visible internal damage

- Recurring faults despite corrections

Call a certified VFD technician if these appear issues occur.

Commonly asked questions (FAQs)

- What is the the most common fault in a VFD?

Many faults are caused from example: Dust, heat or poor airflow. - How do I reset an Emotron VFD fault?

You can clear the active alarm in different ways, depending on the drive. One way is to find the RESET button on the control panel. Press and hold this button to clear the alarm.

- Can a bad motor damage a VFD?

Yes, for example a motor overload can cause overcurrent - Why is my VFD suddenly not working?

There can be numerous reasons, but depending on which model you have, some common issues can be overcurrent during acceleration, undervoltage, overheating or input/output phase loss. - How to fix overcurrent fault?

Stop the drive, check the motor load again, inspect shorts and adjust the acceleration ramp time.

Conclusion

Troubleshooting a VFD doesn’t have to be intimidating. With a structured, practical approach, you can often resolve issues on-site—without delays or unnecessary costs. A dedicated product training and a clear understanding of error codes can help you quickly analyze problems. This way, you can take action before anything is completely broken.